Emirates begins major fleet retrofit project to elevate customer experience

No other airline has handled a retrofit of this magnitude in-house…

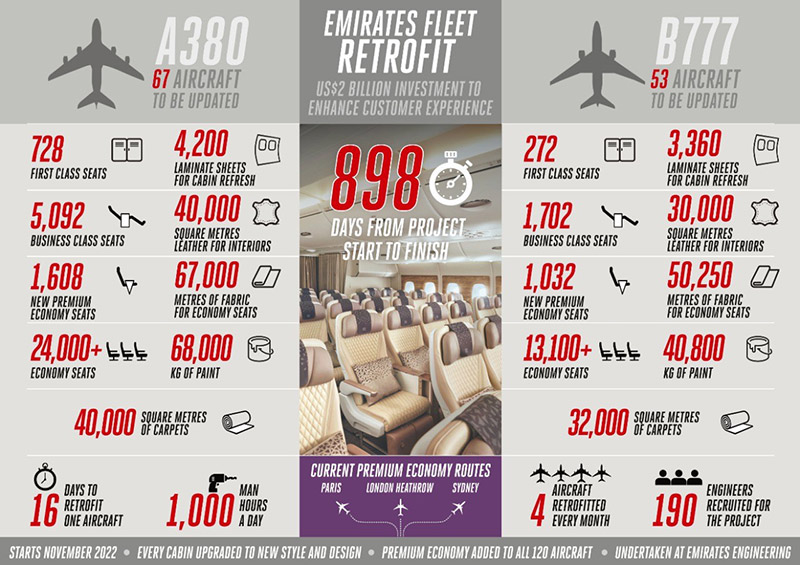

Award-winning Emirates Airlines has commenced its large retrofitting project. The project will see 120 aircraft receiving a total makeover. The retrofitting project focuses on two of the largest commercial aircraft types in service today – Airbus A380 and Boeing 777.

The multi-billion dollar investment project was announced back in November 2021 and will ensure customers have a better flying experience in keeping with their ‘fly better’ campaign.

The retrofit will take place over the coming years and will be completed by April 2025. The project officially commences in November 2022. Emirates will retrofit 67 A380s, and once these planes are back in service, 53 777s will undergo their facelift.

So, what are some of the changes Emirates is incorporating?

Well, the main change includes the installation of nearly 4,000 brand new Premium Economy seats. If you haven’t heard about Premium Economy before, the cream leather seats are wider offering extra comfort. There are 6-way adjustable headrests, calf rests and footrests, so you can sit back and relax. Screens are 13.3 inches and there will be easily-accessible charging points, a wide dining table and even a cocktail table.

According to Emirates, 728 First Class suites will be refurbished with new leather seats, armrests and more. Over 5,000 Business Class seats will also be upgraded to a new style and design including new covers and cushions.

Additionally, the carpets and stairs will be upgraded, and the cabin’s interior panels will be refreshed with new tones and design motifs including the iconic ghaf trees which, as you may know, are native to the UAE.

Here’s another whopping fact for you: 108,800 kilograms of paint will be utilised for the project.

According to Emirates, retrofitting an A380 will take 16 days to complete, while four B777 aircraft can be completed in a month.

During the process, Emirates will plan and test extensively to establish and streamline processes and identify and address any possible snags along the way. For our readers who work in the engineering department, the team quite literally took each cabin apart piece by piece – seats, bolts, screws and all – and each action was tested, timed and mapped.

Images: Emirates